Products Description

[Appearance]

This product generally appears as yellowish-red to reddish-brown, free-flowing, uniform liquid.

[Physical and Chemical Properties]

This product exhibits excellent thermal stability, maintaining its performance in high-temperature environments. It decomposes at temperatures above 160°C while retaining thermal stability at 120°C. It effectively slows down corrosion in oil well equipment, ensuring safe and stable well operation. With outstanding corrosion inhibition performance, it forms a dense protective film on metal surfaces to prevent aqueous corrosion.

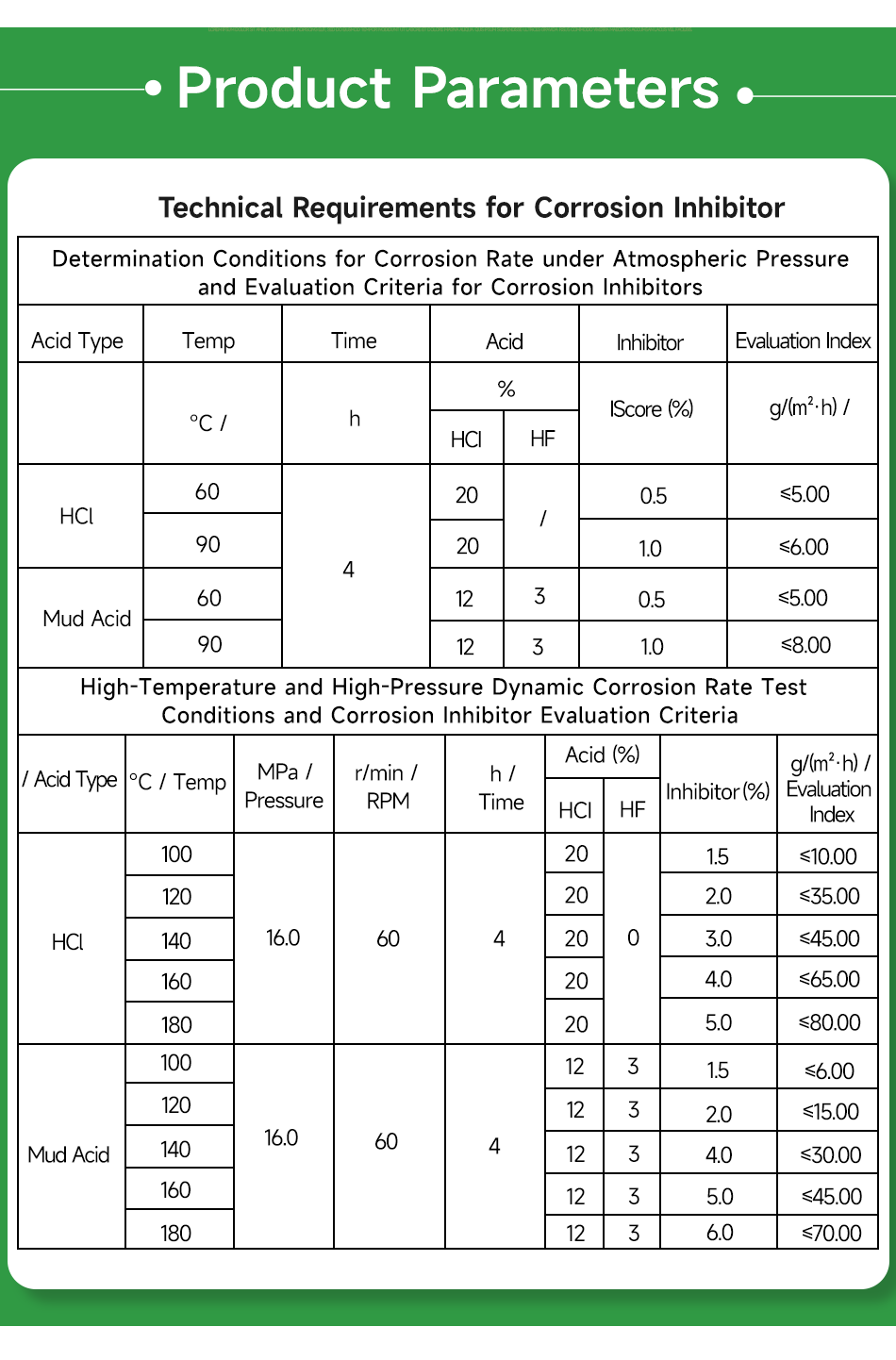

Technical Specifications of Corrosion Inhibitor

| Test Conditions for Atmospheric Static Corrosion Rate Measurement and Evaluation Standards for Corrosion Inhibitors | ||||||||

Acid Type | Test Temperature (℃)_ | Reaction Time (h) | Acid Solution Mass Fraction (%) | Corrosion Inhibitor Dosage (%) | Corrosion Inhibitor Evaluation Index g/(㎡.h) | |||

| HCI | HF | |||||||

HCl | 60 | 4 | 20 | / | 0.5 | ≤5.00 | ||

| 90 | 20 | 1.0 | ≤6.00 | |||||

Mud Acid | 60 | 12 | 3 | 0.5 | ≤5.00 | |||

| 90 | 12 | 3 | 1.0 | ≤5.00 | ||||

| Test Conditions for High-Temperature and High-Pressure Dynamic Corrosion Rate Measurement and Evaluation Criteria for Corrosion Inhibitors | ||||||||

Acid Type | Test Temperature (℃) | Experimental Pressure (mpa) | Stirring Speed (r/min) | Reaction Time (h) | Acid Solution Mass Fraction (%) | Corrosion Inhibitor Dosage (%) | Corrosion Inhibitor Evaluation Index g/(㎡.h) | |

| HCI | HF | |||||||

HCl | 100 | 16.0 | 60 | 4 | 20 | 0 | 1.5 | ≤10.00 |

| 120 | 20 | 2.0 | ≤35.00 | |||||

| 140 | 20 | 3.0 | ≤45.00 | |||||

| 160 | 20 | 4.0 | ≤65.00 | |||||

| 180 | 20 | 5.0 | ≤80.00 | |||||

Mud Acid | 100 | 16.0 | 60 | 4 | 12 | 3 | 1.5 | ≤6.00 |

| 120 | 12 | 3 | 2.0 | ≤15.00 | ||||

| 140 | 12 | 3 | 4.0 | ≤30.00 | ||||

| 160 | 12 | 3 | 5.0 | ≤45.00 | ||||

| 180 | 12 | 3 | 6.0 | ≤70.00 | ||||

[Application]

The primary use of fracturing corrosion inhibitors is to slow or prevent corrosion of metal equipment caused by acidic media during acidizing and acid washing operations in oil and gas wells. It offers excellent corrosion protection against single acids (such as HCl, HF, H₃PO₄) and mixed acids by preventing direct contact between acid solutions and metal surfaces, thereby reducing corrosion.

[Product Advantages]

1. Metal surfaces protection;

2. Low toxicity with broad-spectrum performance;

3. Excellent acid and thermal resistance;

4. Long-lasting corrosion inhibition effect.

[Usage and Dosage]

Dilute this product in warm water (50–60°C) in a ratio of 1:10 to 1:20. Stir until completely dissolved, then add the remaining water to the required volume and stir evenly to ensure a uniform working solution. Dosage can be adjusted based on actual site conditions.

[Packaging]

This product is available in IBC totes (net weight 1000 kg), 200 kg or 25 kg drums. Custom packaging is available upon request. Handle with care during transport. Do not invert. Apply strict measures to prevent leakage or damage during transit.

[Storage]

Store in a cool, dry place away from direct sunlight and high temperatures. Shelf life is 2 years.