Products Description

[Molecular Formula] C₉H₁₁NO

[Molecular Weight] 149.19

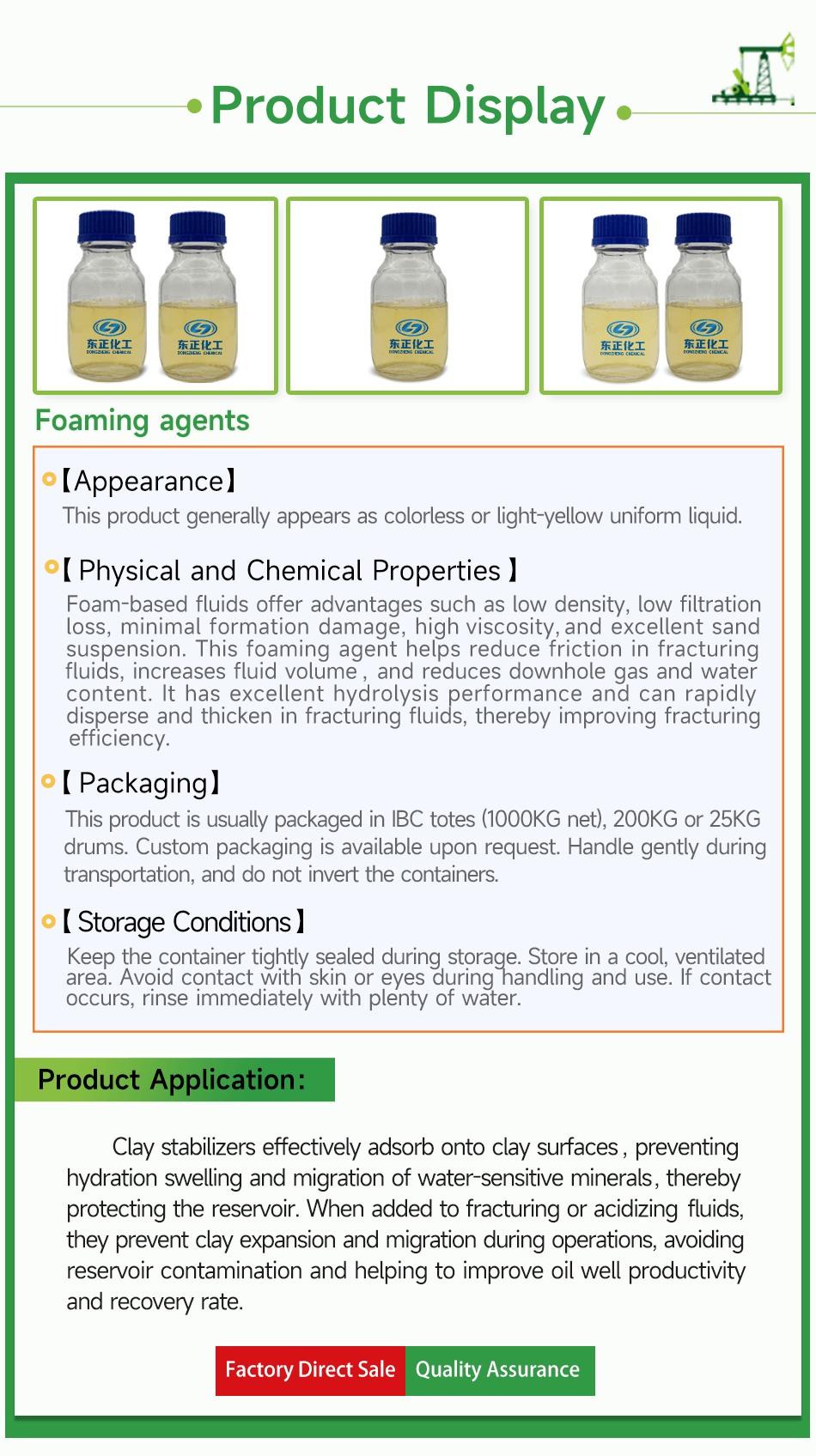

[Appearance] This product generally appears as colorless or light-yellow uniform liquid.

[Physical and Chemical Properties]

Foam-based fluids offer advantages such as low density, low filtration loss, minimal formation damage, high viscosity, and excellent sand suspension. This foaming agent helps reduce friction in fracturing fluids, increases fluid volume, and reduces downhole gas and water content. It has excellent hydrolysis performance and can rapidly disperse and thicken in fracturing fluids, thereby improving fracturing efficiency.

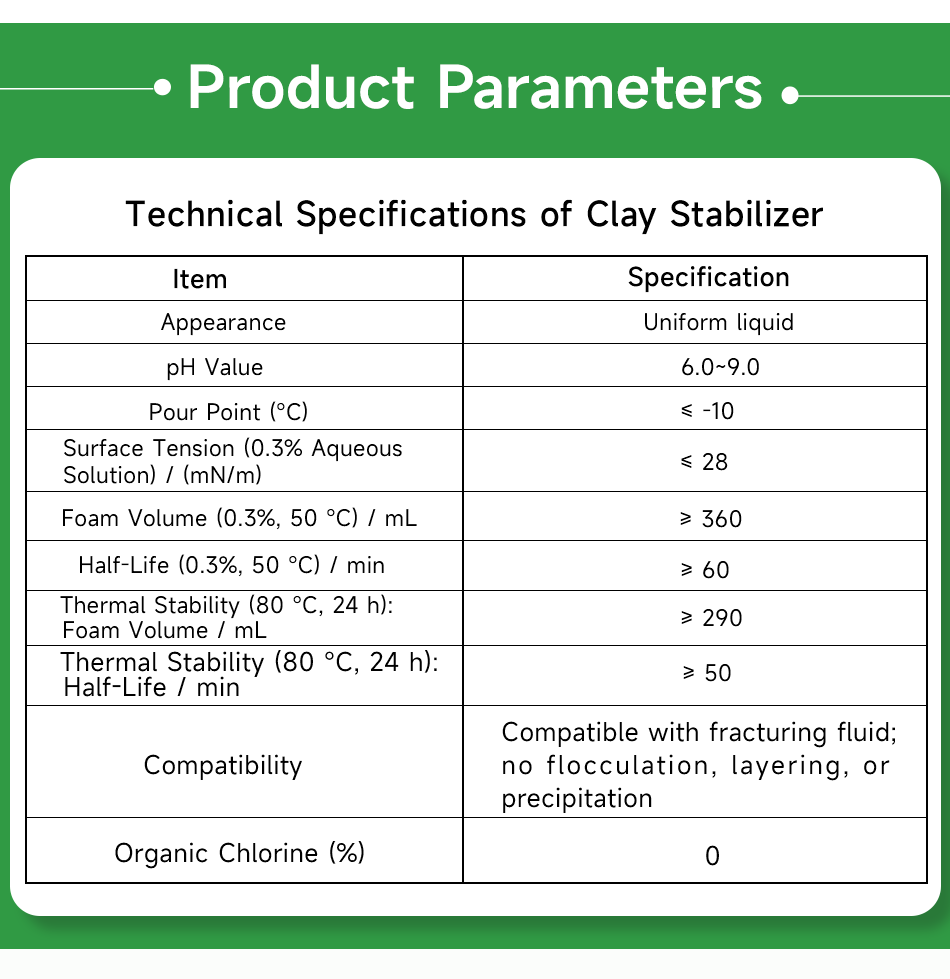

Technical Specifications of Foaming agents

| Item | Specification | |

| Appearance | Uniform liquid | |

| pH Value | 6.0-9.0 | |

| Pour Point (°C) | ≤ -10 | |

| Surface Tension (0.3 wt% Aqueous Solution) / (mN/m) | ≤ 28 | |

| Foam Volume (0.3%,50℃)/mL | ≥ 360 | |

| Half-life (0.3%, 50 °C) / min | ≥ 60 | |

Thermal Stability (80 °C, 24 h) | Foam Volume (mL) | ≥ 290 |

| Half-life (min) | ≥ 50 | |

| Compatibility | Compatible with fracturing fluid; no flocculation, layering, or precipitation | |

| Organic Chlorine (a/%) | 0 | |

| The organic chlorine content test is required only for oil well applications and is not applicable for gas well applications. | ||

[Applications]

Foaming agents are widely used in oilfield operations, including as additives in fracturing fluids, tubing cleaning, and reservoir stimulation. Foam acid formulated with the foaming agent forms bubbles significantly improve fracturing efficiency by generating stable foam structures that reduce fluid friction losses through foam lubrication effects, and increase effective fluid volume via gas entrainment while maintaining excellent proppant transport capacity. These stable foamed acid solutions provide critical operational advantages including gas-assisted liquid unloading and accelerated flowback, ultimately enhancing overall stimulation performance.

[Product Advantages]

1. Improve fracturing performance;

2. Suitable for special formations;

3. Enhance equipment efficiency;

4. Foam acid has low filtration rate and reduces formation contamination.

[Usage and Dosage]

The foaming agent is mainly used in fracturing fluid additives, tubing flushing agents, reservoir stimulation, foam flooding, and acid fracturing. It should be added to fracturing fluid at a specified ratio, typically 0.5%–1% of the total fluid volume. The dosage and concentration should be controlled to maintain optimal fracturing performance, and adjusted based on actual field conditions.

[Packaging]

This product is usually packaged in IBC totes (1000KG net), 200KG or 25KG drums. Custom packaging is available upon request. Handle gently during transportation, and do not invert the containers.

[Storage Conditions]

Keep the container tightly closed during storage. Store in a cool, ventilated area. Avoid contact with skin or eyes during handling and use. In case of contact, rinse immediately with plenty of water.