Products Description

[Structural Formula] SiO₂

[Molecular Weight] 149.1882

[Appearance]

This product generally appears as white or yellow crystalline round granules with strong flowability.

[Physical and Chemical Properties]

This product is made from natural quartz sand as the main raw material. It features high hardness, excellent wear resistance, and good chemical stability, playing an important role in the exploitation and hydraulic fracturing of petroleum and natural gas resources.

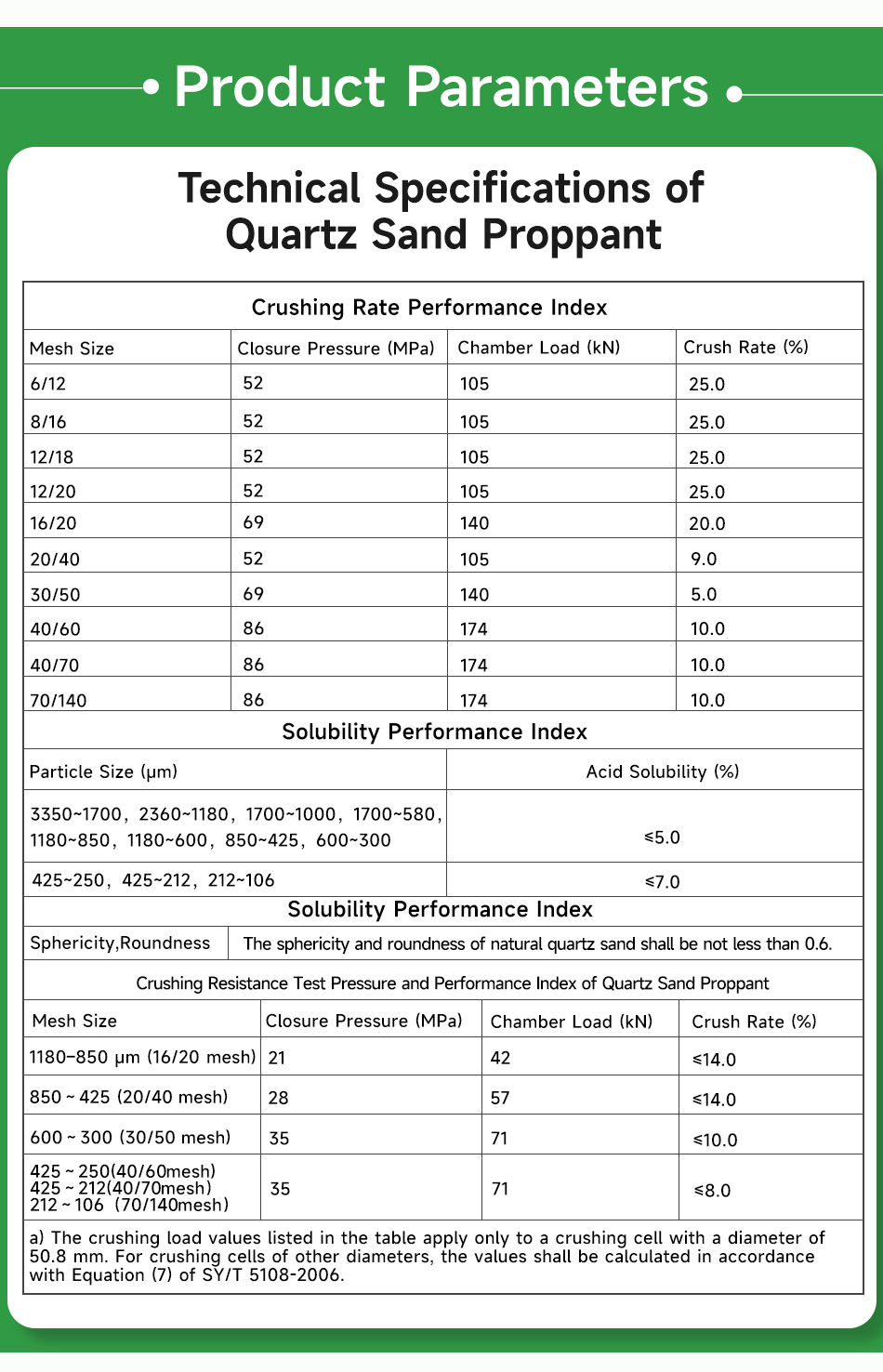

Technical Specifications of Quartz Sand Proppant

| Crushing Rate Performance Index | |||

| Mesh Size (Mesh) | Closure Pressure (MPa) | Chamber Load (kN) | Crush Rate (%) |

| 6/12 | 52 | 105 | 25.0 |

| 8/16 | 52 | 105 | 25.0 |

| 12/18 | 52 | 105 | 25.0 |

| 12/20 | 52 | 105 | 25.0 |

| 16/20 | 69 | 140 | 20.0 |

| 20/40 | 52 | 105 | 9.0 |

| 30/50 | 69 | 140 | 5.0 |

| 40/60 | 86 | 174 | 10.0 |

| 40/70 | 86 | 174 | 10.0 |

| 70/140 | 86 | 174 | 10.0 |

| Solubility Performance Indicator | |||

| Proppant Particle Size Specifications (μm) | Acid Solubility (%) | ||

| 3350~1700,2360~1180,1700~1000,1700~580,1180~850,1180~600,850~425,600~300 | ≤5.0 | ||

| 425~250,425~212,212~106 | ≤7.0 | ||

| Sphericity and Roundness Specifications | |||

| Sphericity and Roundness | The sphericity and roundness of natural quartz sand shall not be less than 0.6. | ||

| Crush Resistance Pressure and Performance Indicators of Quartz Sand Proppants | |||

| Mesh Size | Closure Pressure (MPa) | a / Load (kN) | Crush Rate (%) |

| 1180~850 (16/20 Mesh) | 21 | 42 | ≤14.0 |

| 850~425 (20/40Mesh) | 28 | 57 | ≤14.0 |

| 600~300 (30/50Mesh) | 35 | 71 | ≤10.0 |

| 425~250 (40/60Mesh) 425~212 (40/70Mesh) 212~106 (70/140Mesh) | 35 | 71 | ≤8.0 |

The crushing force value in the table is only applicable to crushing cells with a diameter of 50.8 mm. For crushing cells of other diameters, the value shall be calculated in accordance with Formula (7) of SY/T 5108-2006. | |||

[Applications]

Quartz sand is primarily used as a proppant in the extraction of oil and natural gas. In hydraulic fracturing operations, it is mixed with high-pressure fluids and injected into the reservoir to create fractures, enhancing permeability. It keeps fractures open and forms a high-conductivity pathway from the reservoir to the wellbore, thereby increasing hydrocarbon production.

[Product Advantages]

1. High compressive strength;

2. Stable chemical properties;

3. Excellent corrosion resistance;

4. Strong conductivity;

5. Low production cost.

[Usage and Dosage]

The dosage depends on the wellbore diameter and depth, as well as the ratio of fracturing fluid to quartz sand.

[Packaging]

Typically packaged in bulk bags or in bulk, with net weights of 1000kg or 1500kg. Custom packaging is available upon request.

[Storage Conditions]

Store in a dry and ventilated area, and avoid direct sunlight. Prevent contamination and do not mix different mesh sizes in storage.